Contributing writer Rebecca Marques is the director of custom research for PMMI, the association for packaging and processing technologies.

HERNDON, VA — The snack food industry is undergoing a dynamic transformation, with packaging trends at the forefront of innovation. The latest findings from the Snack Food Packaging Trends report, produced by PMMI, the association for packaging and processing technologies, highlight key shifts shaping the future of packaging, from automation and sustainability to consumer-driven customization. As companies invest heavily in packaging and processing machinery, understanding these trends is crucial for businesses looking to remain competitive in an evolving market.

Growth and investment in packaging machinery

Optimism in the snack food industry is at an all-time high, with 92% of companies anticipating growth over the next three years. This confidence is reflected in increasing capital expenditures on packaging and processing equipment. The industry has witnessed a 10.5% rise in spending, driven by the need for increased productivity, the introduction of new SKUs and enhanced automation. Companies are not only acquiring new machinery but also expanding their fleets, with 88% planning to purchase new equipment in the near future.

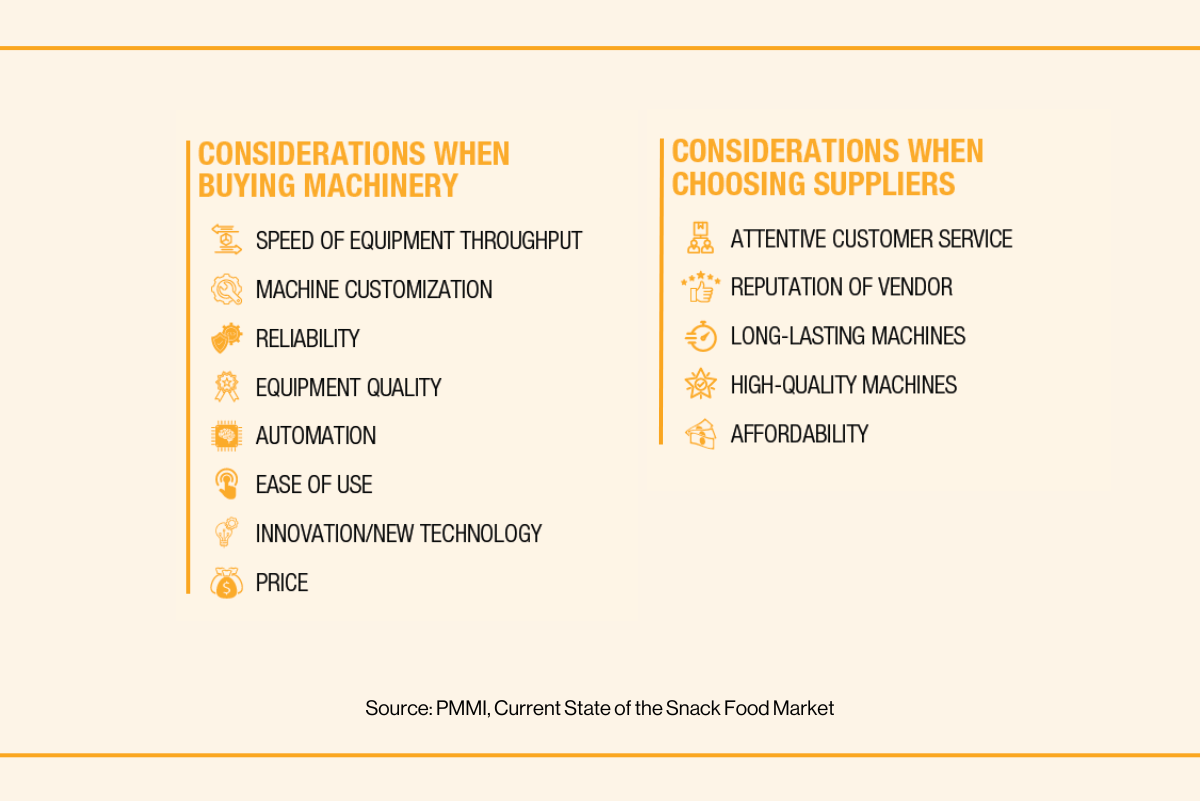

One of the key investment drivers is speed. Companies prioritize machinery with higher throughput and automation capabilities to enhance production efficiency. Many also opt for modular and customizable machinery, allowing flexibility in packaging different product sizes and formats without significant retooling.