WESTMINSTER, CO — In today’s highly competitive, highly regulated food manufacturing environment, source-to-shelf digital systems are a non-negotiable. Integrated, AI-driven systems that communicate flawlessly optimize production floor efficiencies, strengthen traceability capabilities, reduce packaging errors and minimize food safety risks.

Yet, according to the TraceGains report, “Digital Drag: The Growing Gap Between Tech Priorities and Implementation in the Food and Beverage Industry,” only 6% of companies surveyed said they have having fully integrated digital solutions.

Additional research conducted by TraceGains found teams across food, beverage, private label and adjacent industries struggle with siloed systems, email-based approvals and limited visibility into how changes ripple across SKUs.

Increasing packaging complexities mean greater risk

Commercial bakeries often focus on upgrading front-end systems to optimize operational efficiencies on the production floor. However, packaging systems often remain on the periphery.

“Traditionally, packaging teams have used different systems,” said Paul Bradley, senior director of product marketing for TraceGains. “In many cases, they have a different supply chain, so their sourcing and specifications may live in a different place from food product specifications.”

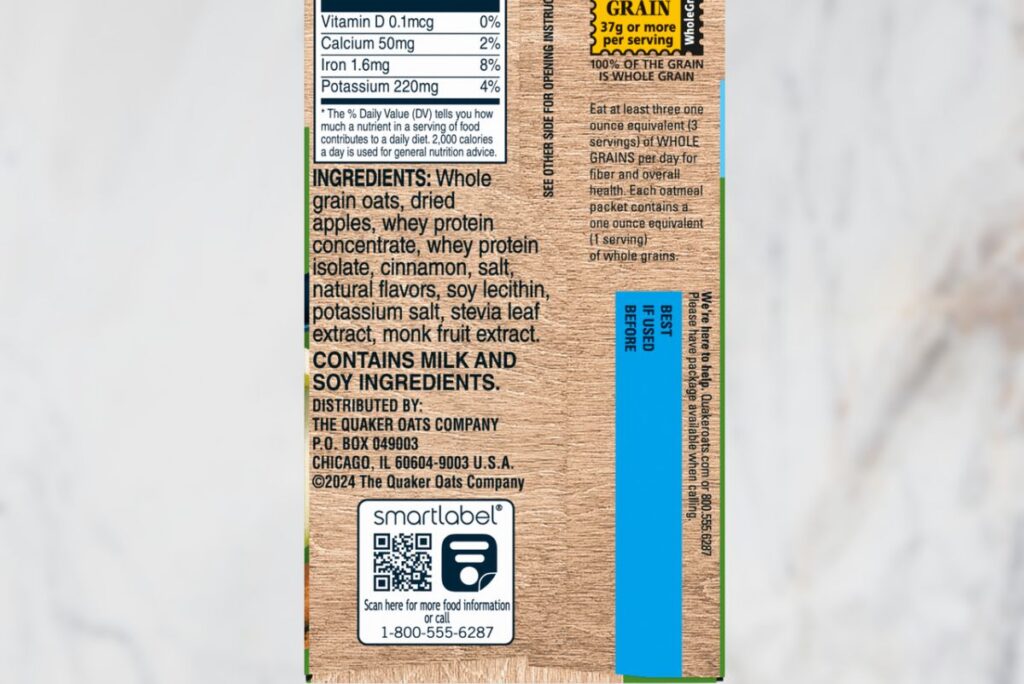

Yet, as packaging complexities increase, this system separation increases the risk of errors, especially when, in the rush to market, ingredient changes and allergen declarations aren’t communicated to packaging and artwork teams in time.

To address this challenge, TraceGains launched Packaging Specification Management, featuring native integration with portfolio partner Esko’s WebCenter Go packaging artwork management solution. The system unifies ingredient specifications, packaging data, product formulas, finished goods and artwork approvals into a single system.