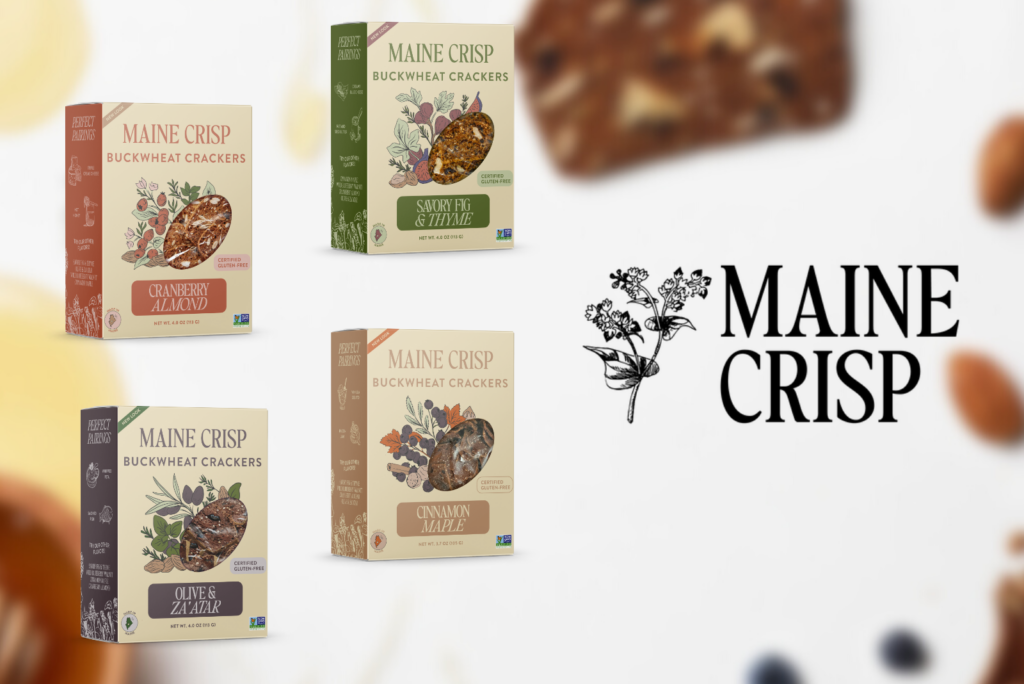

WINSLOW, ME — After cutting the ribbon on a new production facility in October, Winslow, ME-based artisanal snack manufacturer Maine Crisp also debuted its packaging upgrade. The new design reflects the product’s core attributes, including its premium flavor and clean-label formula. The package also touts the benefits of buckwheat, a superfood ingredient at the foundation of Maine Crisp’s product lineup.

The new packaging employs whimsical illustrations of buckwheat, a soft color palette, and a window to convey approachability and transparency. Studio Linear, a creative firm founded in Maine, led the project.

“My mission is to create better products for people, and our new package design really highlights the sense of naturalness that I strive for,” said Karen Getz, founder and president of Maine Crisp.

Grown along Maine’s Canadian border, the naturally gluten-free buckwheat inspired Getz to create a snack with purposeful ingredients that would satisfy both gluten-free and gluten-loving consumers. Getz launched the company in 2014 with one flavor: Cranberry Almond. Today, Maine Crisp offers four flavors, including the vegan bestseller, Savory Fig & Thyme.

The packaging upgrade is just one benefit that has come with the increased production capacity afforded by the new facility, which will accelerate the company’s national growth.

In 2021, as national distribution deals with UNFI and KeHE drove substantial increases in demand, Maine Crisp planned renovations to a vacant building in Winslow. Now transformed into a certified gluten-free facility, the 17,000-sq.-ft. space enables the company to launch new product lines and offer co-packing services to gluten-free food startups.