Unparalleled innovation

Then again, some innovation at the new bakery is changing the game in a totally different way. An all-CO2-driven freezer system supports the warehouse freezer and the one in production. It’s not only environmentally friendly but also eases total cost of ownership for freezing.

“The system is set up to handle cooling for the whole plant,” Cramer said. “We don’t have to add anything to it. That’s where bottlenecks happen, when we have to think, ‘How am I going to cool all of this? How much more ammonia do I need to add?’ But it’s all CO2, so it’s also environmentally friendly.”

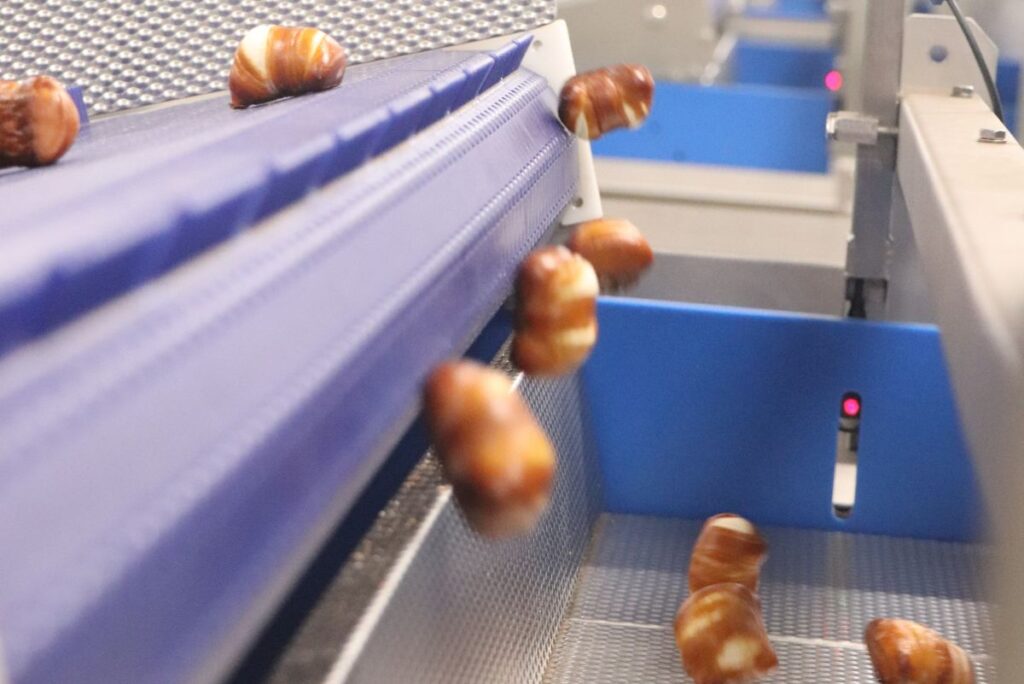

As the brand rides a wave of “Americanized” pretzel innovation in the US, the company is expanding its reach throughout all of North America … and beyond. Many food trends in the US are spinoffs of European originals, but that doesn’t mean they can’t make their way back across the pond, gaining attention of their own.

“The global market has come to really want Americanized things,” Stefanik said. “There are many people overseas who are intrigued by what we’re doing with our pretzel bites.”

That intrigue is converting to sales as Ditsch USA begins exporting orders overseas.

“But it only works when we stay true to our roots,” he added.

With all that’s happening, this isn’t the “Wild West” for pretzel making. The company’s stage-gate process ensures product development is done with intention, regardless of the speed. Creativity doesn’t mean the team simply lets imagination run wild. Even while stretching the limits of pretzel innovation, it must maintain Ditsch’s brand integrity and always stay true to the original formula.

“Do we want to bend to the left or right a little?” Schroeder observed. “Yes, we do. That’s important. But long-term, we must stay consistent, and development has to meet those standards.”

With room in the new bakery to add at least four more lines, as well as create space for dedicated distribution and on-site R&D, growth will come at the pace demand dictates.

“We’ve created a ‘plug and play’ situation,” Stefanik said. “With it, there’s no challenge we can’t face.”

The USA team has struck a balance between honoring a century of Ditsch’s expertise — and even more history of its product — with adopting new technology and adapting to modern American tastes. The result is a group of “pretzel ambassadors” presenting this product like never before.

“New” for the sake of being new doesn’t work here. No matter how innovative the products or technology are, Ditsch USA will stay true to its core, ensuring every product fits the time-honored process and quality standards of the brand.

“We don’t call them ‘bites of happiness and pretzel love’ for no reason,” Stefanik said. “We love every aspect of that dough, from start to finish.”

This story has been adapted from the October | Q4 2025 issue of Commercial Baking. Read the digital edition here.