KANSAS CITY, MO — Remember back in 2014, when Vani Hari, known around the blogosphere as “Food Babe,” sent the commercial baking industry into upheaval with her petition against Subway?

Hari called for the sandwich chain to remove the dough conditioner azodicarbonamide (ADA) from its bread, noting the chemical was also used in the manufacturing of yoga mats and shoe rubber. Even though ADA had GRAS status from the FDA, the petition still sent shock waves through the industry, causing bread suppliers — not only for Subway but in channels everywhere — to drop everything and reformulate.

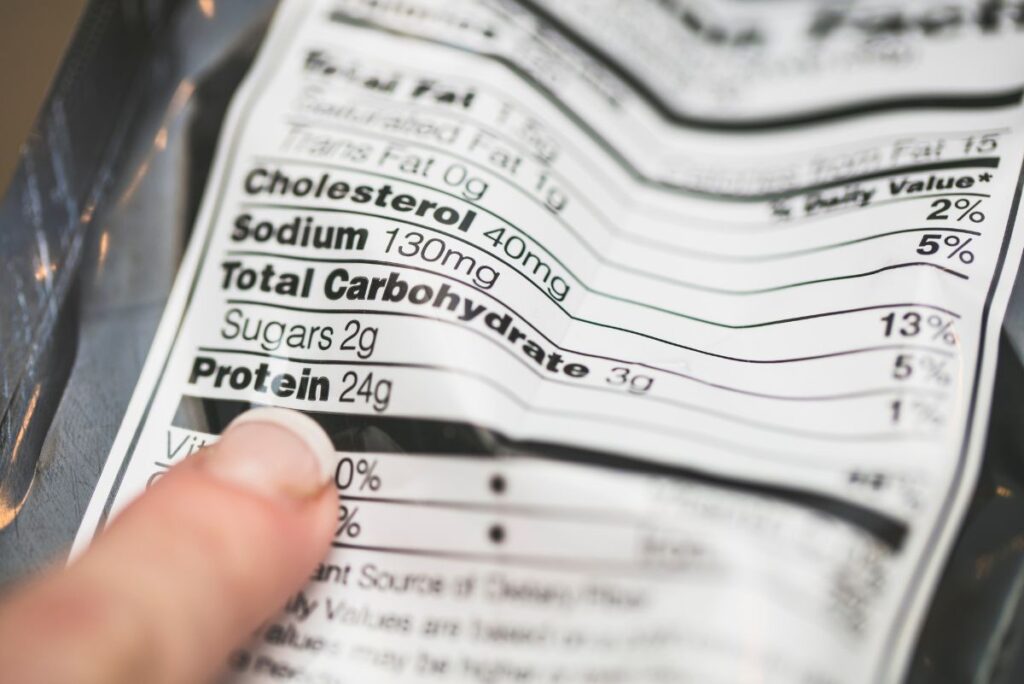

In an ideal world, a clear set of initiatives is outlined in advance of the reformulation process and its several stages. Before R&D teams can roll up their sleeves and get to work, they must understand what’s driving the reformulation. Whether the need is related to nutritional targets, cost considerations or consumer perception, it’s crucial to identify potential ingredients that contribute to the end goal without sacrificing the quality of the finished product.

“That involves looking into technical data, regulatory status, functional properties and perhaps consulting with supplier partners to review market benchmarks and consider consumer perception areas,” said Kendall Howie, principal food scientist at the Middleby Bakery Innovation Center. “It’s not just about finding an ingredient that ‘works.’ It’s also about finding one that aligns with the product, brand identity and production realities.”