Building out the agents and data structure varies from operation to operation, but taking the time to do so in a way that makes sense for each particular company makes it easier in the long run.

“I can’t emphasize enough, this thing will grow as you utilize it for various parts of the operation,” Ybarra said. “It’s just going to learn.”

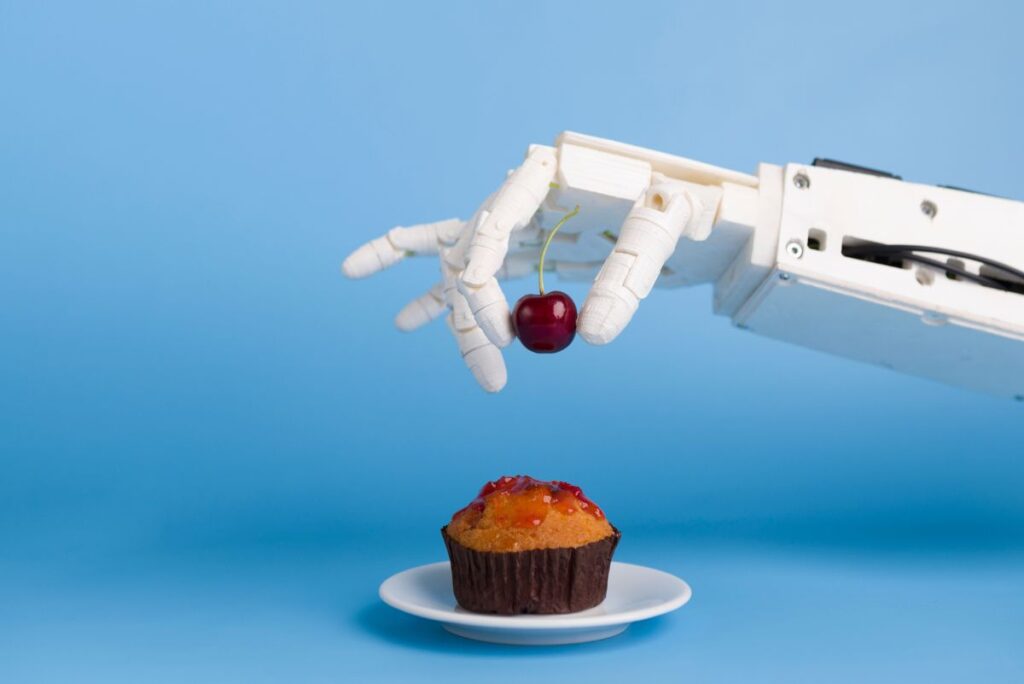

In addition to bakeries, AI is influencing how manufacturers design and build equipment. Brandon Brilliant, president of AMF Americas, outlined the potential behind integrating the technology directly into machinery.

“We talk about how to create training models, segment data and impart legacy knowledge of all the retiring folks onto new teams,” he said. “What if we can take that data and legacy knowledge and impart it onto that machine itself without needing to do operator personnel training?”

AI can be used in several areas of baking operations, including preventive maintenance, determining the perfect mix time, and instant temperature adjustments in the oven. Making these changes begins with data collection. Bakers can add the tools needed to their existing equipment to harness critical insights and connect with their IT teams to ensure data is processed in a way that best aligns with each business’ needs.

“We believe the biggest impact areas are going to be on mixing, oven and packaging systems,” Brilliant said, “so we want to start making real-world applications and differences in those areas.”

To set a strong foundation for widespread use of this technology, Brilliant noted that equipment manufacturers need to set a benchmark for how they plan to adopt and integrate AI.

“We’ve got a responsibility as an industry to set some of the standards right now,” he said. “We’re on the cusp of exploration and early adoption. There needs to be some common industry expectations and standards that make this as effective as it could be from the start.”

Getting started

Cross-industry collaboration with manufacturers from other sectors, such as semiconductors, that have already implemented AI can save bakers a lot of grief as they begin to work through the technology themselves.

“The kinds of things [semiconductor manufacturers] are doing with the integrations of PLC programming, the ways they’re capturing data and making automatic adjustments are universal in manufacturing,” Brilliant said.

While some may be hesitant to begin using AI, the BIF team believes the time to learn about it — and embrace its potential — is now. The benefits can extend externally, too. Introducing

AI also opens the door for baking companies to provide better service to customers.

“I see this being another piece of equipment to help us honor efficiencies and provide better value to customers,” said Justus Larson, VP of operations for Portland, OR-based Franz Family Bakeries. “If we can lower our costs down to the customer, we can provide a high-quality product for a lower price point.”

For leaders unsure of where to begin, Larson suggested taking time to test out the technology and identify colleagues who can carry the banner for what AI can do for the business.

Porter echoed that sentiment, noting that AI is the future of baking.

“If you want to be a relevant company and be competitive in the marketplace, you better embrace AI,” he said. “It’s coming, and there’s nothing to be afraid of.”

This story has been adapted from the 2025 Innovations Annual of Commercial Baking. Read the full story in the digital edition here.