An initial round of funding from friends and family enabled the brothers to do a small pilot run in Pennsylvania at a co-manufacturing facility that had a mini cracker line and that didn’t require full batches.

“We were going to do 80-lb. batches, which is still a lot of product, but it was a manageable number to explain to people,” Francisco said. “Come the first PO, we could reproduce this at a larger scale.”

From there, the Pergolas invested in branding and marketing, which included developing a website and social media presence, to get the word out about Cheddies.

As the pair worked to bring their product to market, they hit a pandemic-sized speed bump, which made ingredient acquisition challenging for Cheddies’ core ingredient: cheddar cheese. Due to the time it takes for cheese to age before it can be used — and the inability to stock up on supply as CPG giants bought up the cheese reserves during COVID — the Pergolas found themselves sourcing the ingredient from various suppliers.

“There was a bunch of fresh, two-week-old and one-month-old cheese, but we didn’t need that,” Francisco explained. “It put us in a fragile situation where we were buying a quarter pallet out of Vermont and a quarter pallet out of Wisconsin, and it was unbelievably costly.”

He also noted that the varying cheeses impacted product quality.

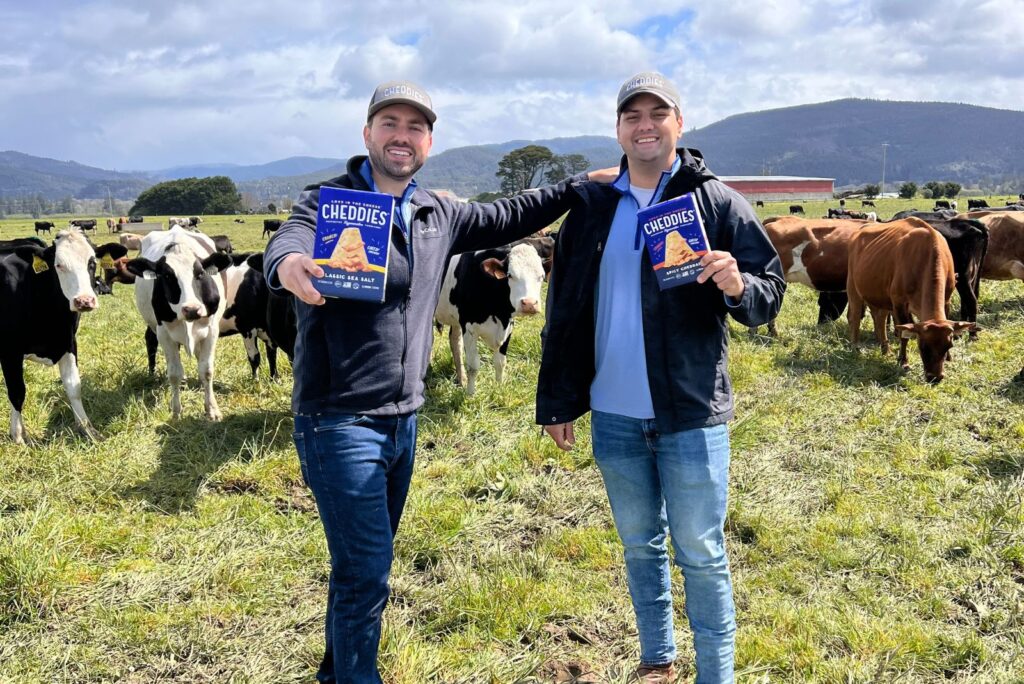

In brainstorming ways to prevent another cheese shortage from limiting their operations and maintain consistent quality for Cheddies, the Pergola brothers looked into how they could create their own cheddar cheese.

“It’s not a terribly complicated process by any means, so we got to researching,” Francisco said. “We want to be the best cheese cracker out there, not just another cheese cracker. To be the best cheese cracker, we have to use the best cheddar cheese.”

This story has been adapted from the October | Q4 2023 issue of Commercial Baking. Read the full story in the digital edition here.