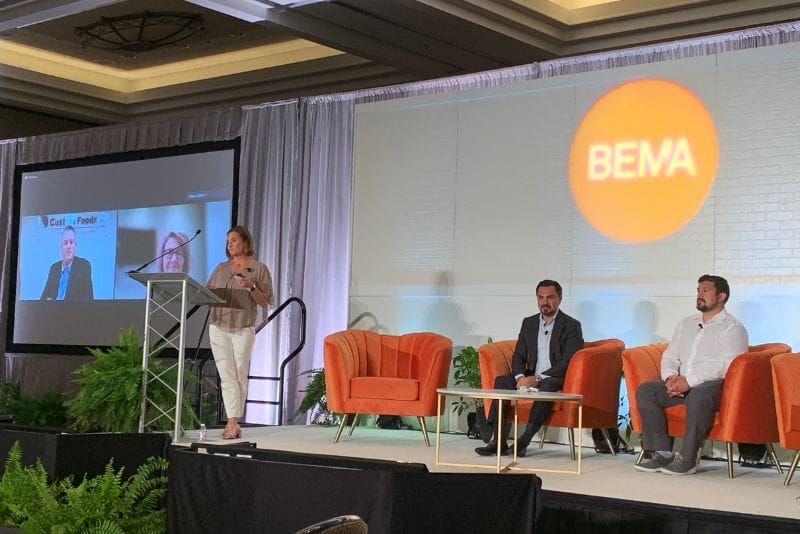

MARCO ISLAND, FL — When it comes to success in quick service restaurants (QSR), flexibility and communication are the names of the game. That’s what members of the QSR Business Panel, hosted by Commercial Baking’s editor-in-chief Joanie Spencer, preached as they answered questions at the BEMA Convention today.

The panel involved two pairs of QSR and bakery partners: Hector Morales of Aspire Bakeries and Anthony Tsocanos of Subway, and Ethan Hart of Custom Foods and Farrellynn Wolf of Goodcents. They discussed the hard-hitting days of the pandemic, how to move forward efficiently and changes they’re seeing as in-person life resumes while an online presence still remains strong.

Companies in the QSR space had to be creative and resilient throughout the pandemic. It was hit hard, with nearly 110,000 temporary and permanent restaurant closures over the course of 2020. But sales rebounded to pre-COVID levels in March through April of 2021, signaling a promising future for the years ahead. Factors such as limited seating; being takeout-friendly and price-friendly; and offering comforting, classic food led to the resurgence in growth.