YORK, PA — JLS Automation has announced plans for expansion of its headquarters, which will focus almost exclusively on increasing production space to accommodate rapidly growing demand for large, automated packaging systems as well as traditional JLS equipment.

The company plans to add 50,000 sq. ft. to the existing facility, which currently is just under 100,000 sq. ft.

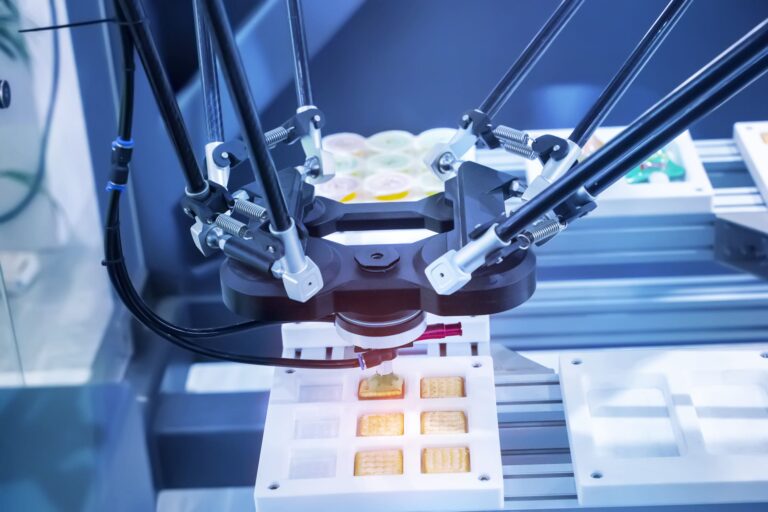

With this addition, throughput opportunities will be increased by 60%, according to the company. It will also provide room for integrating large, high-speed, multi-robot systems. Additionally, the space will allow for a higher volume of factory acceptance testing (FAT) to be conducted onsite, including FATs for fully integrated systems. Onsite testing will ensure end-user success before a system leaves the door while also reducing the time between the test and operation at the final site.