CHICAGO — Many machines are essential to efficient and cost-effective bread production, but it’s possible that you may be overlooking the tiniest and mightiest of all: enzymes.

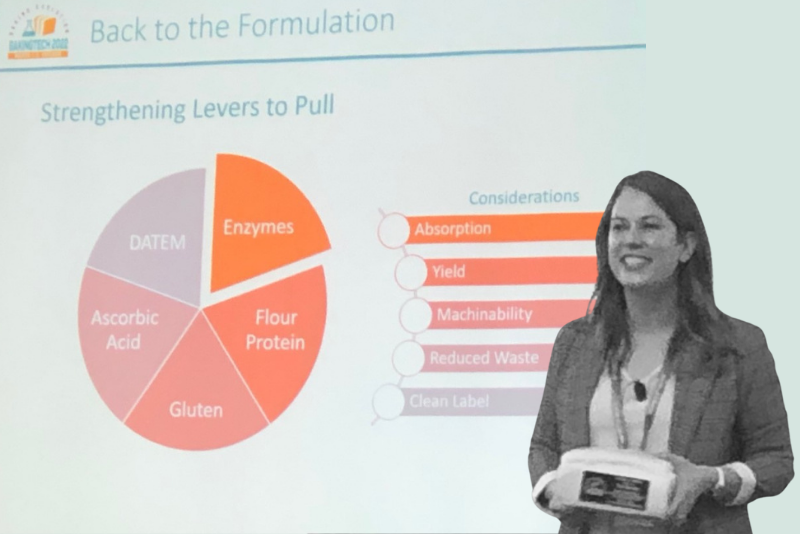

Tess Brensing, senior production manager of functional systems for Corbion, highlighted the many benefits of enzymes for quality breadmaking during the American Society of Baking’s BakingTECH 2022 event in Chicago. Perhaps the most important thing that enzymes can do is alleviate some dependency on vital wheat gluten, which is increasingly more expensive and more difficult to come by.