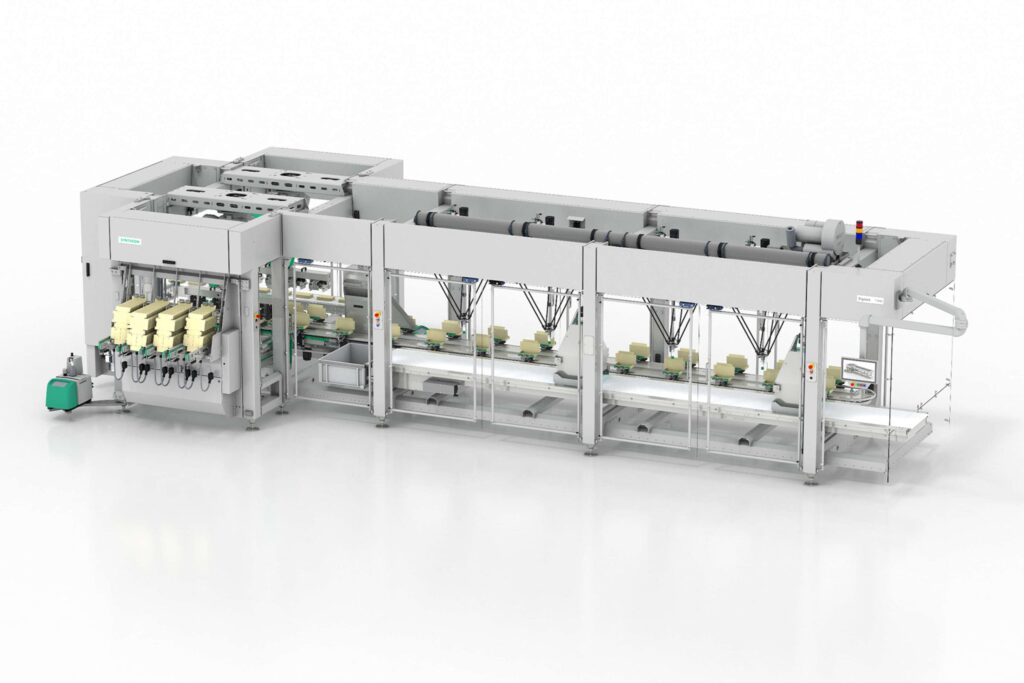

BERINGEN, SWITZERLAND — Syntegon’s Sigpack TTMD combines core technologies of the TTM platform with one or more seamlessly integrated Delta robot cells. The camera-based vision control system detects products on the infeed belt. The delta robots pick single or multiple products arriving in random order and reliably place them in cartons, trays or other containers according to specifications. To enable additional packaging flexibility, the new top-load cartoner can also simultaneously pack different products from several infeed processes. The Sigpack TTMD uses the proven tool-less format changeover concept from the TTM platform, enabling a vertical restart after each format change.