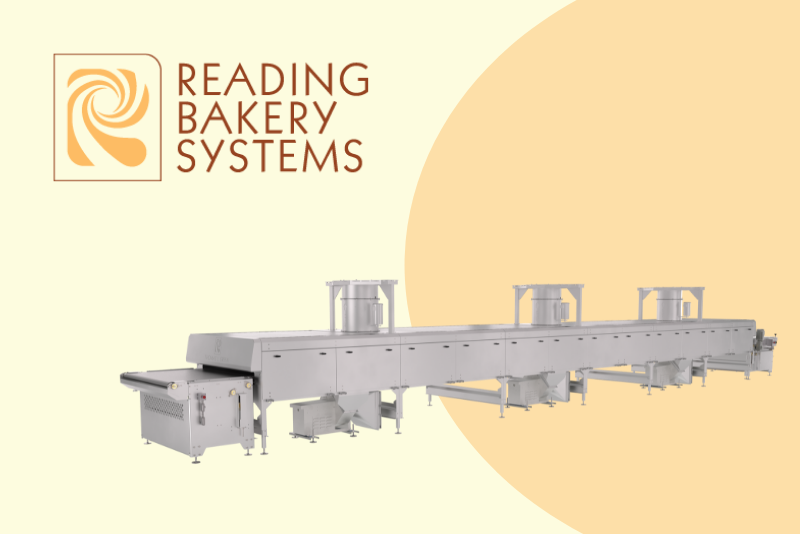

ROBESONIA, PA — Reading Bakery Systems (RBS), a leading global manufacturer of snack production systems, has introduced a new ambient cooling conveyor that can cool crackers before entering packaging, all with a more compact footprint.

Before crackers hit the packaging stage, they must be cooled to a specific temperature to prevent condensation once the package has been sealed. If condensation occurs, it can compromise the snack’s texture and shelf life. Optimal product moisture and temperature control is critical for snacks to remain at peak quality, something RBS is focusing on with this new product.