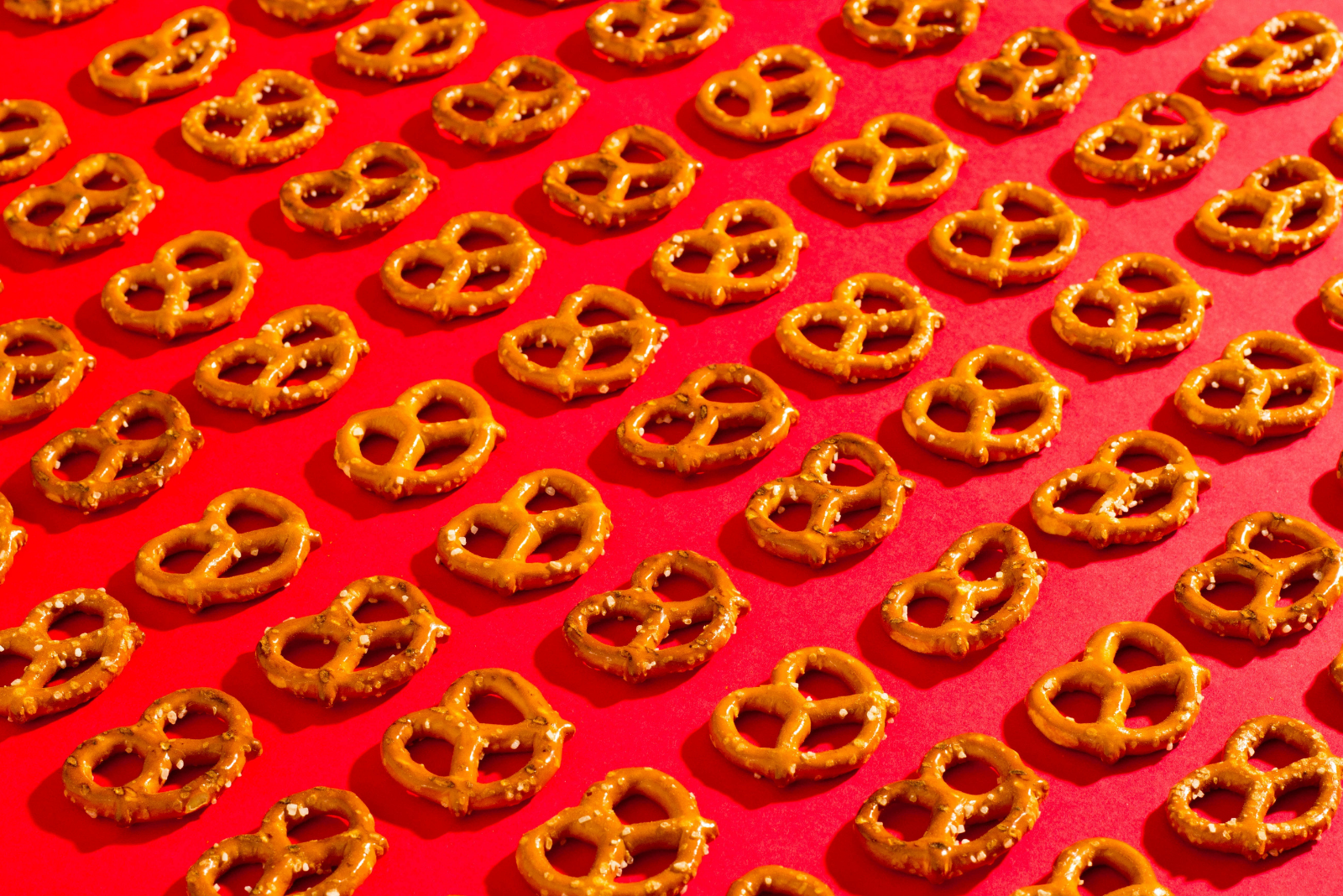

BLANDON, PA — In the world of classic snacks, the pretzel is held dear.

Hungry at a county fair or a ball game? Having a sweet or salty crunchy craving? Need an excuse to dip something in cheese? A pretzel is there to satisfy. But as COVID-19 turned food trends on their heads, the pretzel category has also faced new demands, challenges and opportunities. Hard and soft pretzel producers are facing the new world of snacking head-on.

Unique Snacks’ Reading Bakery Systems oven, which it purchased in 2013, is still going strong.

Although the pandemic pushed the pretzel industry into new territory, the shift had been in motion for years. Health-and-wellness trends and new flavor combinations are evolving at breakneck speed, and it’s certainly changed the game for experienced pretzel producers. Justin Spannuth, VP and COO of Blandon, PA-based Unique Snacks, said that the new snacking landscape can cause a bit of whiplash, but it also presents new areas for success.

“People want innovation of any sort as long as it’s new,” he said. “They want sustainable, organic, non-GMO, and a lot of those needs that exist now weren’t here 10 years ago. So, we’re focusing on getting new products in front of people, and there are a lot of nuances to it.”

Unique Snacks, formerly known as Unique Pretzels, has its hands in many pots of the hard-pretzel world, including its signature original “Splits,” sprouted pretzel shells, sprouted original Splits, chocolate-coated pretzels and “chocolate crunchies,” which are chocolate bites stuffed with peanut butter and pretzel morsels. And the pressure to add more products that meet different needs is on.

Meeting those needs can be a tall order, especially for trends like gluten- and grain-free. Although Unique Snacks isn’t producing gluten-free items yet, as the team talks with others innovating in that space, it’s always learning something new.

“I’ve spent 20 years understanding baking technology to achieve a high-quality product with wheat and gluten, and now 90% of products have alternate ingredients because people don’t want wheat and gluten,” Spannuth said. “From trying to understand these new ingredients and how they work in different environments to understanding what those product bases taste like and how they change things like topicals, you’re always learning.”

“From trying to understand these new ingredients and how they work in different environments to understanding what those product bases taste like and how they change things like topicals, you’re always learning.” —Justin Spannuth | VP and COO | Unique Snacks

For soft pretzels, the demand for innovation is less based on flavor or ingredients than shape. From bites to braids to sticks, soft pretzel producers are on a quest to find the latest and greatest contortion. This is especially true for Milwaukee Pretzel Co., a Bavarian soft pretzel manufacturer with products in foodservice, e-commerce and frozen grocery.

For soft pretzels, the demand for innovation is less based on flavor or ingredients than shape. From bites to braids to sticks, soft pretzel producers are on a quest to find the latest and greatest contortion. This is especially true for Milwaukee Pretzel Co., a Bavarian soft pretzel manufacturer with products in foodservice, e-commerce and frozen grocery.

“People always ask us for a pretzel version of this and a pretzel version of that,” said Matt Wessel, owner and president of Milwaukee Pretzel Co. “They want circles, stars, braids. But we have to look at it both in terms of what we can make and what we can make quickly enough to justify selling.”

Although Milwaukee Pretzel has evaded challenges in its flavor innovation, it’s still had to overcome some production hurdles.

“Of course, we need mixers and ovens, and as we get bigger as a business, we need to scale our equipment up,” Wessel said. “But when it comes to German pretzels and the caustic soda application, that machinery is more specialized. And a lot of times it’s coming from overseas, so lead times are longer and the cost is higher.”

Caustic soda, more commonly known as lye, is a high-pH solution applied to pretzels and similar products such as bagels that results in the brown, tangy and crunchy exterior with that soft interior. But since the pH is so intense, it can be dangerous for employees to handle; that’s why Wessel places a high priority on critical safety training.

When it comes to health-and-wellness and flavor trends for Milwaukee Pretzel, the team is sticking to what it knows. The pretzel formula is tried and true, and there’s not much interest in altering what works. Although health and wellness trends aren’t the primary target, this product does come with a hidden benefit: Bavarian pretzels have no added sugar.

“We don’t put sugar into our pretzel dough, and a lot of American doughs do that to create a sweeter pretzel,” Wessel said. “Ours is savory and has a rich flavor profile. We don’t overly promote the ‘no added sugar,’ but we definitely let people know it’s a sugar-free product.”

At the end of the day, Wessel hopes to merge the artistic touch of a baker’s hand with an automated factory that’s fit for Mr. Wonka himself.

“We love employing people, but if we could somehow have that Charlie and the Chocolate Factory experience, where you see a product go from dough creation to packing, that would be awesome,” he said. “Particularly on the lye application side since the caustic soda can be dangerous to work with. And with the pretzel transfer that’s so disruptive to the dough, that would be gratifying. Not only is it better for the product, but it would also be a nice reduction in a type of work where the employees would rather focus on something else.”

With all the explorations in flavors, fillings, shapes and sizes, pretzels are reaching new heights. But no matter the innovative ways to switch up this snack, it will always be a classic.

Read more in the October | Q4 issue of Commercial Baking. Photos courtesy of Unique Snacks and Milwaukee Pretzel Co.